April I-II, 2025

March I-II, 2025

Frebuary I-II, 2025

January I-II, 2025

December I-II, 2024

November I-II, 2024

October I-II, 2024

September I-II, 2024

August II, 2024

August I, 2024

August I, 2024

July II, 2024

July I, 2024

June II, 2024

June I, 2024

May II, 2024

May I, 2024

April I, 2024

April II, 2024

March II, 2024

March I, 2024

February II, 2024

February I, 2024

January II, 2024

January I, 2024

November I, 2023

December II, 2023

December I, 2023

November II, 2023

October II, 2023

October I, 2023

Septiembre II, 2023

Septiembre I, 2023

August II, 2023

August I, 2023

July II, 2023

July I, 2023

June II, 2023

June I, 2023

May II, 2023

May I, 2023

April II, 2023

April I, 2023

March II , 2023

March I , 2023

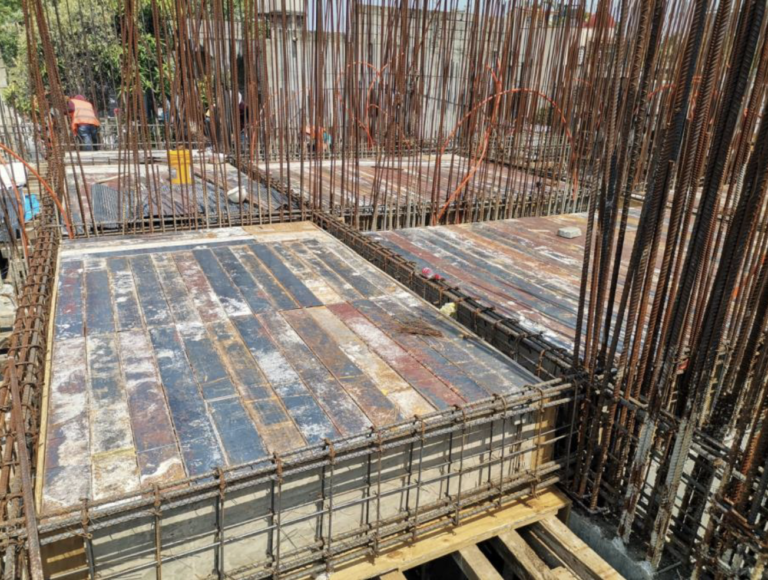

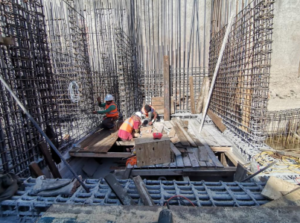

Arrival of steel to the construction site. / Work continues on the reinforcement of the bottom slab, counter beams, dice and concrete walls. / Works are being carried out to clean up the rubble resulting from cutting piles. / Arrival of falsework for concrete walls. / Arrival of accessories for metallic formwork.

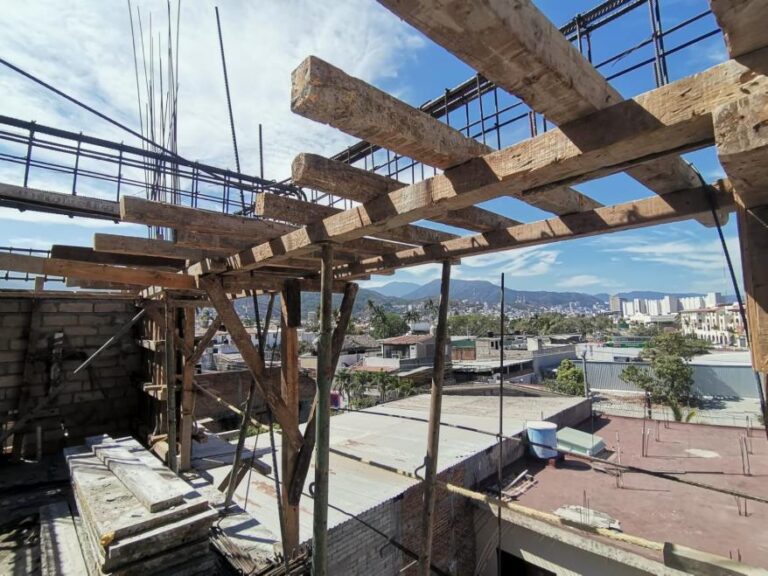

Formwork work begins on adjoining walls. / They continue with the assembly of dice and counter beams that will later be casted. / Metal formwork reinforcement works continue. / Preparations are left to continue shoring adjoining walls. / Arrival of the pump to strain background slab elements.

Casting and work with concrete vibrators continues. / Clearing of ground section bottom slab and previous excavations. / The electrical installations of the storage rooms (switch and contacts) were done.

February, 2023

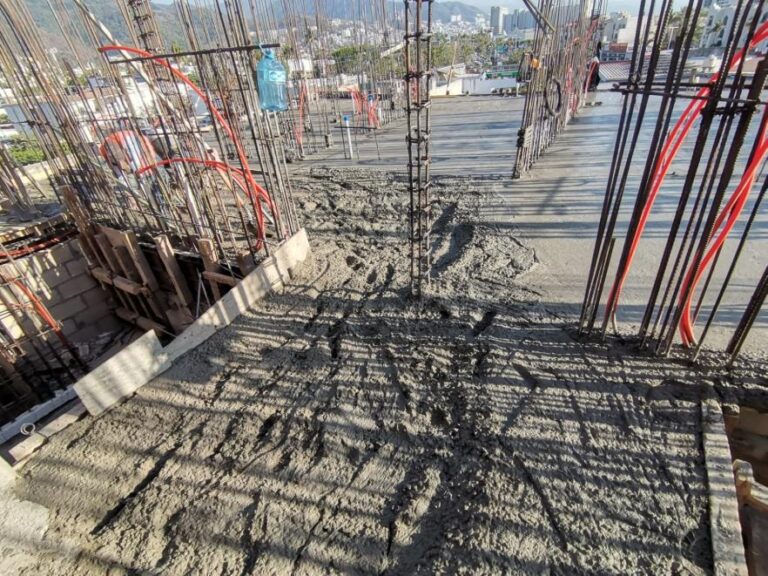

Delivery of rod and steel for elements such as counter beams. / Elements continue to be assembled on the transition slab grill. / Worktables are placed to be able to assemble and handle wood. / Material is purchased to detail when casting the transition slab level. / The workers activate the pump and strain begins.

The workers used the helicopter for polishing. / After polishing, cleaning and detailing work is done. / The first stage transition slab is left as clean and detailed as possible./ Concrete joints are detailed and sealed. / Cleaning and detailing work is done on the 2nd stage background slab./ The excavation area is left clean and detailed with fondaline.

Visit of the work expert to fill out the log. / Arrival of rod to continue CTB girders./Material for electrical installations was brought. / The assembly of the counterbeams continues./You enter the cistern area and the transition slab that has been casted. / The cistern area is left clean and detailed.

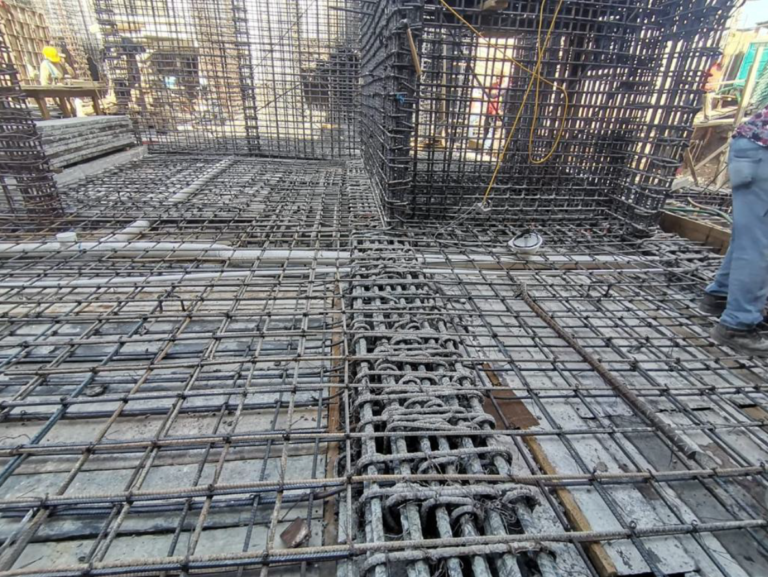

Fondaline is placed below before beginning to assemble the second section with more counter beams and dice. / They begin to make overlaps in rods to continue upper side assembly. / Rods protruding from piles are straightened. / Rods are joined by overlapping.

Arrival of steel to the construction site. / The arrival of steel is used to assemble more stirrups for dice and counterbeams. / Stirrups of different measures are ready. / Construction site view with armed stirrups.

January, 2023

Arrival of steel and rod on site to make more stirrups. / Everything is prepared for casting. / We continue with the casting.

Formwork removal work continues. / Arrival of excavator 320 at the site to carry out work. / Dump trucks are filled with dirt and debris left over from the work.

Use of a hydraulic rotary hammer with a backhoe for pile removal. / Demolition is almost ready, cleaning and detailing the template are next.

November – December, 2022

On week 17, corresponding to the month of November, preparation of the land is being done as well as the filling of the floor with 4” graven.

The poor concrete template is placed f’c=150 dried for 3 days with a thickness of 10 cm. / To later receive the assembly of the slabs and grade beams.

The images show the template finished up to the Q axis. Leveling will continue in stage 2 along with the compression of the rest of the ground.

In week 18 corresponding to the month of November, work is being done on the demolition of pile capping.

We continue with the assembly of stirrups for dice and grade beams. / Pile rod bends according to leveling for preparing the assembly of dice and grade beams.

We begin the excavation of the adjoining missing sides of the middle of the field.

During the excavation process, we continue with the extractions of mud resulting from the process. Mud is carried out with the backhoe and loaded into trucks.

September – October, 2022

After grading, backhoes were required to begin excavation about the established cut levels. To complete this process, dump trucks were required to remove the remains of the excavation.

Excavation work continued with machinery and transportation of waste in dump trucks.

After a certain stage of the excavation, the slopes required for the correct functioning of the bank are shaped, since it was considered that the properties of the soil in which it is located are poor instability.

At this stage, work has continued by hauling mud and soil from the deep excavation with the backhoes; the mud is transported by dump trucks.

The layout, excavation and cleaning of the excavation process iscompleted, making the bank route clear.

August – September, 2022

During week 10 corresponding to the month of September, work was carried out to clean up the sludge from the previous excavation; the material was hauled by backhoes which transported the sludge to dump trucks which took it away.

During the week, work continued on cleaning up the mud resulting from the previous foundation processes, and the images show it being hauled away by backhoes and dump trucks.

After cleaning up the mud on the site, the drill cans were also removed by back hoes, which were then taken by dump trucks to their destination.

July – August, 2022

Drilling and anchoring of piles of different diameters